- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

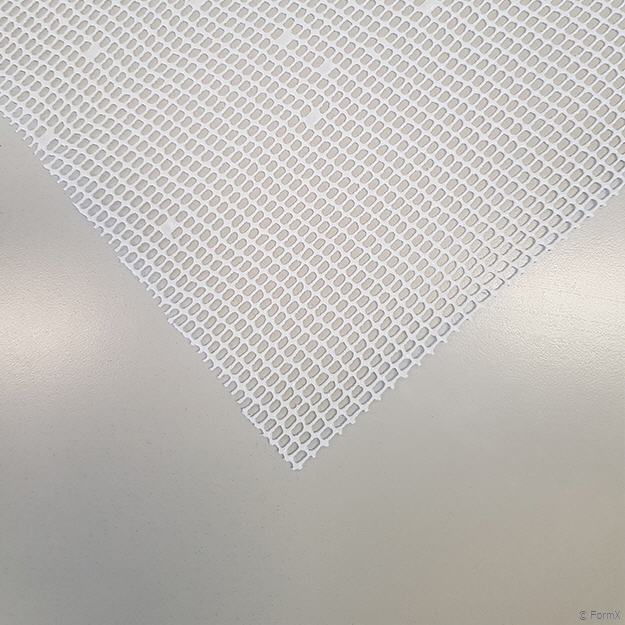

Varaform Heavy

Varaform is a lightweight, rigid and remoldable thermoplastic that has been used for years in the medical and veterinary industry, as well as for theater, stage, screen and conservation efforts. It’s archival, non toxic and skin safe. It’s easy to use and activates at 70°C

Varaform Heavy

Here are the basics of using Varaform, some points from the manufacturer's fact sheets, some from our own experience.

Insert Varaform vertically into 71° C water. Keep the material under water until air bubbles stop rising. Varaform will soften in 30 seconds. Varaform should not be kept in the water longer than 30 minutes.

If you need to work in multiple layers, it’s easier to do so by bonding sheets together first. Line up the grid and spot heat, pinching to bond the layers together. You can then heat the combined sheets as one unit.

Once removed from water, let it drain so that it becomes cool to the touch and ready to apply. Allow to drain 10-15 seconds before applying.

Working on a protected surface (parchment paper or a silicone sheet to prevent sticking) heat the Varaform evenly with the heat gun. If working with a large shape over a form, it may be easiest to place the sheet over the mold and heat directly over top.

Important- Work with wet hands and wet tools! Varaform is sticky and will try to stick to everything. You can use saran wrap or aluminum foil as a barrier on molds, and water helps keep it from sticking to your tools and hands.

Once activated, you have roughly 3 minutes of working time before it starts to set. While active, Varaform can be folded, tucked, stretched or

notched to achieve maximum contouring. Mold as you use each piece, going slow and steady: don’t try to rush. If your Varaform cools too fast, or if you wish to remold a specific area, apply heat to the area with a heat gun until the material is pliable.

Setting time for Varaform depends upon the thickness, project size, and room air temperature. A 3-layer section will set in 3-5 minutes at an average room temperature. Rigidity will be achieved after 10 minutes. Maximum strength of a thick section is attained in 30 minutes.

The number of layers needed to create Varaform scenery, jewelry, face masks, costume interiors or puppet heads varies. Adequate strength can usually be

achieved with 1-2 layers. Areas requiring extra rigidity should be reinforced with splints and total 3-5 layers.

To remold any section of the Varaform material, soften the area by carefully applying heat with a 1000-watt portable hair dryer or heat gun. As soon as the material has softened, it is ready for remolding.

Soften the area to be repaired as you would for remolding, then apply a new piece of heated Varaform to the softened area and rub gently around the edges for the best bond. Rough spots may be smoothed by gently pressing after the material has been softened.

Single layers may be re-used 2-3 times without compromising the thermoplastic characteristics. If Varaform has been heated but not used, it can be cooled while flat and used again.

Epoxies that will stick to the Varaform fabric may be used to fill in perforations to give a smooth surface, if desired. Varaform will accept a variety of coatings and paints. Small pieces should be used for experimentation to insure that the projects desired outcome is achieved.

Keep your Varaform in a cool, dry location. Do not leave in your car or other areas prone to overheating. Temperatures above 125º F may soften the material. Varaform meets the requirements of the Flammable Fabrics Act.

Varaform may be cleaned by using a damp, not wet sponge.

SHIPPING LARGE VOLUME - LOW WEIGHT

Please note that for shipment of large volume products such as Thermoplastic sheets, EVA foams and Large sculpting forms, VOLUME will be calculated rather than WEIGHT.

When ordering these products we will quote you separately for shipping AFTER you have placed your order with us. Thank you for your understanding.

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.