- Home page

- 3D Printers and accessoires

- Modeling

- Molding & Casting

- Tin Silicones

- Platinum Silicones

- Dragon Skin™ Series

- Ecoflex™ Series

- Equinox™ Series

- Mold Star™ Series

- Rebound ™ Series

- Smooth-Sil™ Series

- SORTA-Clear™ Series

- Body Double™ Series

- Psycho Paint™

- Platsil Gel & Deadener

- Rubber Glass ™

- Encapso® K

- Solaris™

- Soma Foama™

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- PU-Rubbers

- Alginate

- PU-Resins

- PU Foam

- Epoxy Resins

- Polyester Resins

- Gypsum & Cement

- Latex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica Latex Rubber

- Monstermakers Foam Latex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Coating/Dipping Latex

- Holden's Body Latex™ - Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- AcrylCast

- Prince August

- Concrete Mixtures

- Jesmonite Acryl System

- Buddy Rhodes™ Concrete Products

- Seal and Release

- Additives

- Pigments

- Jesmonite liquid Pigments

- Pure Pigments powder

- Ultra Fine Pigments powder

- Silc Pig™ pigments for silicone

- Glow Worm™ Fluorescent Pigments

- Cryptolyte™ Glow in the Dark

- Silicone Pigments - SilcPig™ Electric fluorescent

- Siltone Pigment for Silicone

- SilTone Kits

- Silicone Coloring System - FuseFX

- Silicone Coloring System S.A.M

- Key Pigments for silicone

- Kryolan Flock Fiber

- Latex Pigments

- Polyester Pigment

- UVO™- PU-pigments - UV-Resistant

- SO-Strong - PU-pigments

- Ignite™ fluorescent PU-pigments

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Powders

- Paints

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint™ Metallics

- Vallejo Acrylic Paints

- Vallejo Metal Color

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- MM Latex Paint

- MM Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Fillers and Finishing

- Solvents & Thinners

- Adhesives

- Tools

- Equipment

- Special Make-Up

- Cannom Grease Paint

- Skin Illustrator Palettes

- Skin Illustrator Liquid

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60 ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Concentrates

- Fleshtone liquid Concentrate 60ml

- Dark Fleshtone liquid Concentrate 60ml

- FX liquid Concentrate 60ml

- FX liquid Concentrate 120ml

- Alchemy liquid Concentrate 60ml

- Grunge liquid Concentrate 60ml

- Mardi Gras liquid Concentrate 60 ml

- Necromania liquid Concentrate 60ml

- Necromania liquid Concentrate 120ml

- Concentrate Alphabetical

- Skin Illustrator Singles

- Skin Illustrator Glazing Gels

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Palettes

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Old Age Stipple

- Holden's Cosmetic Latex™

- Tattoo Sheets

- Brushes Make-Up

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special effects

- Prostetic Materials

- Help me choose

- Literature

- FormX Academy

Mold Max™ Tin Silicone

Buy Smooth-On at FormX

Smooth-On is one of the worlds leading manufaturers 3D modeling materials such as mold-making, casting and special effects materials but also industrial casting resins, adhesives and equipment. FormX is main distributor of Smooth-On products in Europe.

Mold Max™ Series Silicone

High quality polycondensation Silicone with colorcodings.

Mold Max™ Silicones are tin-cured silicone rubber compounds that have exceptional tear strength, working properties and library life. Mold Max™Silicones feature Smooth-On's exclusive "Libra" catalyst for long library life. They cure overnight and feature knotty tear propagation (if the rubber is torn, the tear quickly terminates in a "knot" reducing further mold damage).

Accessories:

Mold Max™ silicones can be thickened with Thi-vex thickener to achieve a paintable consistancy. A fast catalyst is available for the Mold Max™30. Ripped molds can be restored with Silpoxy silicone glue.

Available hardnesses:

Shore A10 -- Mold Max 10

Shore A15 -- Mold Max 14NV

Shore A20 -- Mold Max 20

Shore A29 -- Mold Max 29 NV

Shore A30 -- Mold Max 30 - Mold Max Stroke - -Mold Max XLS II

Shore A40 -- Mold Max 40

Shore A60 -- Mold Max 60

Technical bulletin Mold Max 10-20-25-30-40 series

Technical bulletin Mold Max 14NV

Technical bulletin Mold Max Stroke

Technical bulletin Mold Max XLS II

Technical bulletin Mold Max 60

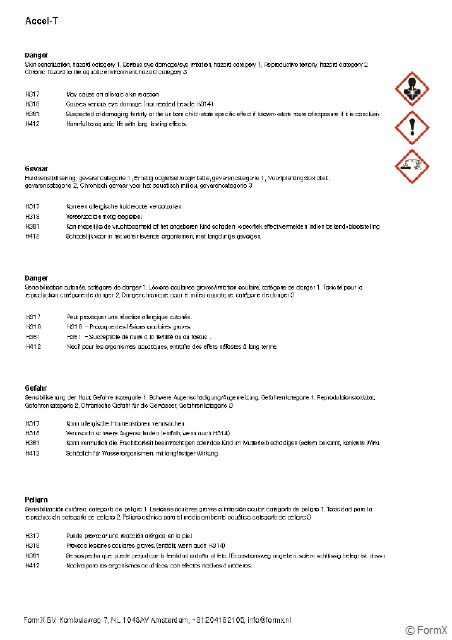

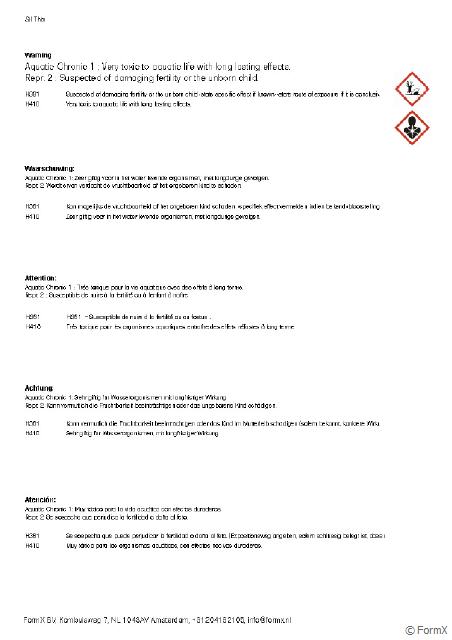

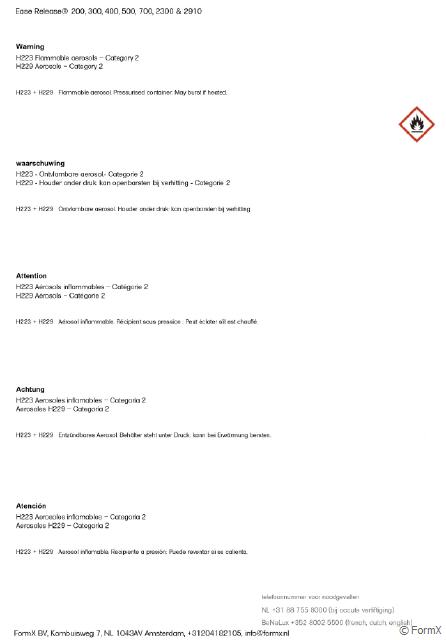

MoldMax Safety Label

- Read the safety information label. Click on the image

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

Mold Max 10

Mold Max 14NV

Mold Max™ 14NV

Mold Max™ 14NV is a Shore 14A tin-catalyzed silicone rubber that offers low viscosity, fast cure and long library life. Mold Max™ 14 NV does not require vacuum degassing. Mix ratio is 100A:10B by weight. Working time is 40 minutes and cure time is 4 hours at room temperature Color is White. Mold Max™ 14NV will reproduce the finest detail and is suitable for a variety of industrial and art related applications including making molds for reproducing prototypes, furniture, sculpture and architectural elements.

Mold Max™ 14NV can also be used to create movie special effects. Cure time can be reduced with Accel-T™ cure accelerator. Mold Max™ 14NV can be used to cast a variety of materials including wax, gypsum, low melt alloys/metals and urethane, epoxy or polyester resins.

Important - Do not cast concrete into rubber molds made with this product. Concrete will not cure properly and inhibition will result.

Important - you must weigh Part A & B components using a gram scale to be successful with Mold Max™ 14NV.

FEATURES

- Mold Max™ 14NV has a fast cure time - 4 hours at room temperature

- Mold Max™ 14NV does not require vacuum degassing

- Low viscosity for easy mixing and pouring

Mold Max 20

Mold Max 25

Mold Max 29NV

Mold Max 30

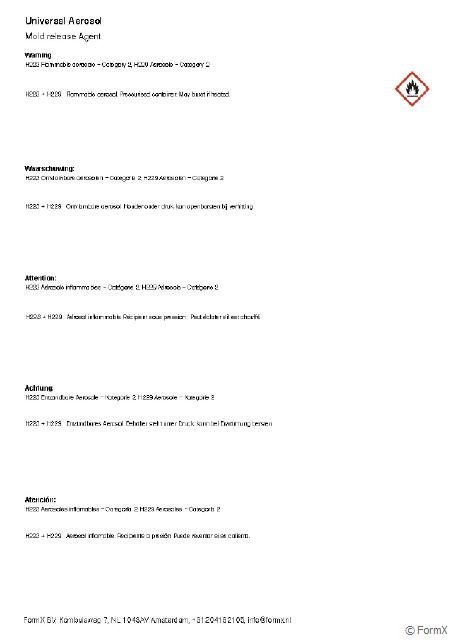

Mold Max Catalyst Safety

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

Mold Max 30 Accessoires

Mold Max 40

Mold Max 60

Mold Max Stroke

Mold Max™ Stroke

Mold Max™ STROKE is a brushable tin silicone rubber that self-thickens for making fast brush-on molds of almost any model. Properly applied, it will hold a vertical surface and will reproduce the finest detail.

Mixed 100A:10B by weight, rubber quickly develops thixotropy and can be applied with a brush or spatula.

Working time is 30 minutes, re-coat time is 45 minutes and cure time after the final layer has been applied is 16 hours at room temperature.

Mold Max™ STROKE silicone will not stick to most surfaces and will cure with negligible shrinkage to a strong, flexible Shore 30A rubber. 4 thin layers is all that is necessary to make a strong and durable production mold for casting wax, gypsum, concrete or resins (urethane, polyester, etc.). Applications include reproducing sculpture, architectural restoration, candle molds, etc.

FEATURES

- Holds a vertical surface

- 4 thin layers is all that is necessary to make a strong and durable production mold

- Color: White

Mold Max XLS

Mold Max™ XLS II

Mold Max™ XLS™ II is a Shore 30A tin-catalyzed silicone mold rubber that exhibits very low long-term shrinkage. XLS™ II molds last longer than other silicones in production when casting chemically harsh resins such as epoxies and polyesters as well as urethane foams.

Mix ratio is 100A:10B by weight. Pot life is 40 minutes and cure time is 24 hours at room temperature. Color Blue

Mold Max™ XLS™ II silicone will reproduce the finest detail and is suitable for a variety of industrial and art related applications including making production molds for, reproducing prototypes, furniture, sculpture and architectural elements. Mold Max™ XLS™ II can be thickened with THI‑VEX™ additive for brush-on applications.

Vacuum degassing mixed material using a vacuum pump and chamber to remove entrapped air is recommended.

FEATURES

- Exhibits very low long-term shrinkage

- High resistance to chemically harsh resins such as epoxies and polyesters as well as urethane foams.

| name | mixing ratio | elongation at break | viscosity | hardness | tear strenght | color |

|---|---|---|---|---|---|---|

| MM-10 | 100A:10B | 529% | 15.000 cps | 10 A | 100 pli | light pink |

| MM-20 | 100A:10B | 512% | 20.000 cps | 20 A | 110 pli | light pink |

| MM-30 | 100A:10B | 300% | 25.000 cps | 30 A | 125 pli | pink |

| MM-40 | 100A:10B | 250% | 45.000 cps | 40 A | 120 pli | light green |

| MM-60 | 100A:3B | 132% | 20.000 cps | 60 A | 63 pli | heat resistant castable in lead and pewter |

| MM-Stroke | 100A:10B | 300% | pasteus | 30 A | 125 pli | brushable silicone |

| MM-XLS | 100A:10B | 375% | 30.00 cps | 30 A | 110 pli | extra low shrinkage, polyester resistant |

Safety Information

Mold Max accessoires

Mixing, Measuring & Weighing

Brushes

Protective Gear

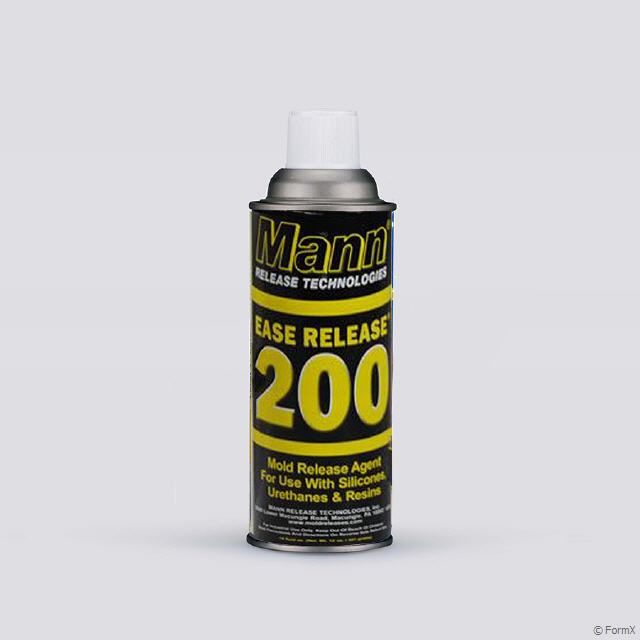

Release Agents

Guide

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.